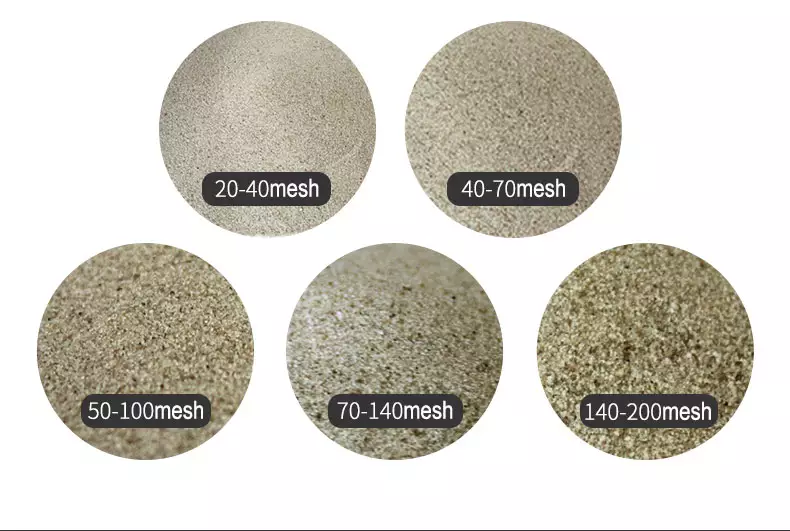

Resin Coated sand:

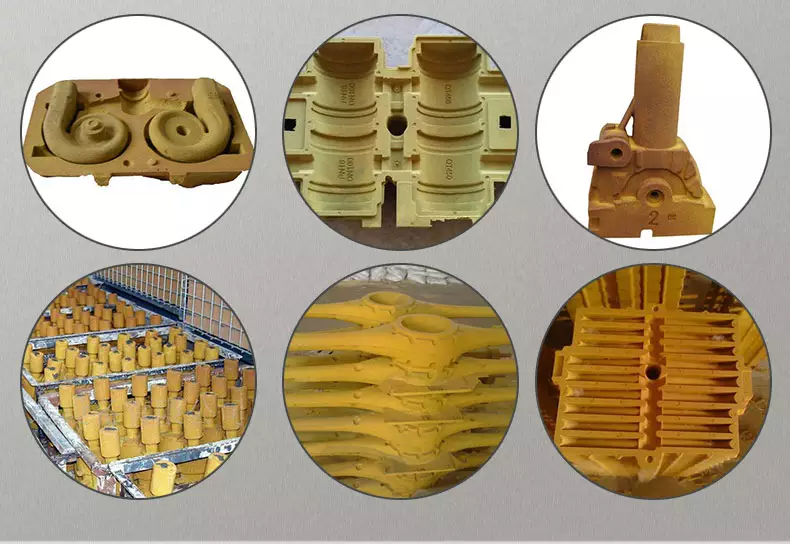

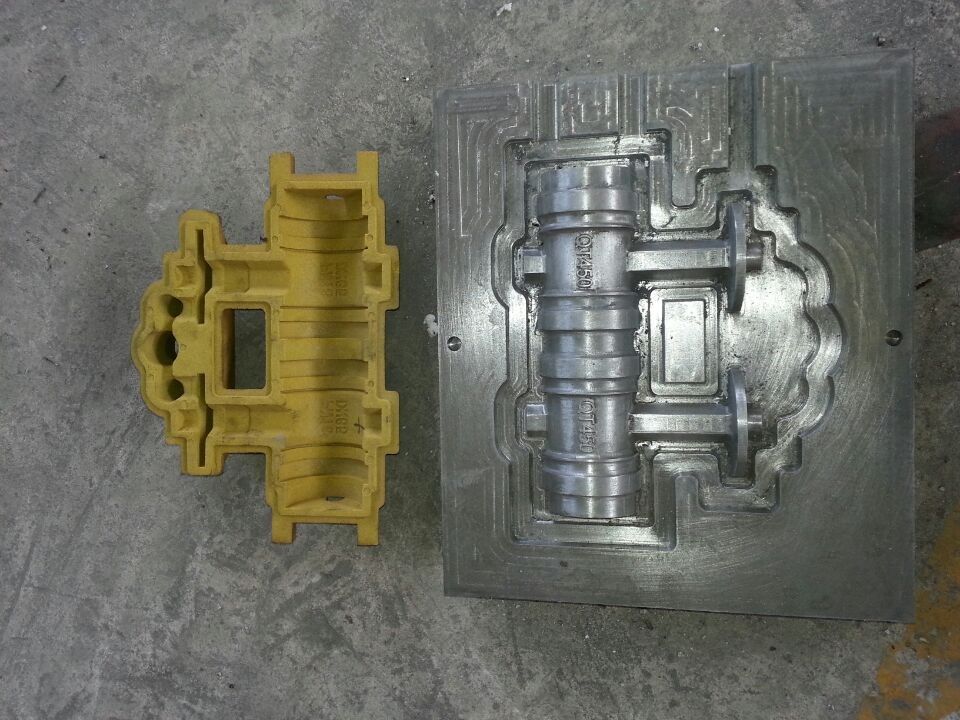

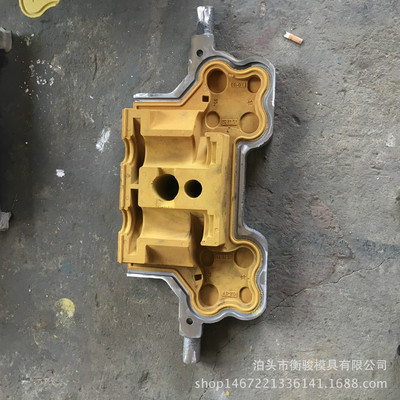

Benefits of resin coated sand as moulding sand of casting precoated sand:

1.Castings can be produced with close tolerance and with very minimum machining allowances along with excellent surface finish.2.Self life of the resin coated sand is unlimited.

3.Hollow cores can be produced.

4.3No crack of core or shell.

5.High transverse strength.

6.Low density of Raysons Resin Coated Sand gives maximum output.